-

APPLICATION

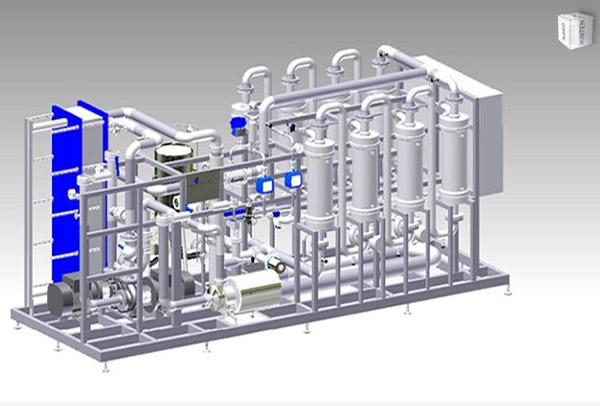

Dissolved oxygen has adverse impact on flavour stability and shelf life. The deaeration system DGS removes O2 from water that is used for the production of beer and beer-based mixed drinks. Deaeration is done at ambient temperature. The system is compact and easily expandable.

-

DESCRIPTION

Based on the use of highly effective membrane modules, extraordinarily low values of residual oxygen are achieved. Each module contains thousands of hydrophobic, gas permeable hollow fibre membranes resulting in a large surface. This large internal surface of the modules maximizes the transfer area and the contact time between water and gas. While the strip gas (CO2 or N2) is applied on the inside of the hollow fibres, the water flows in counter current between them on the outside. The high partial pressure difference of O2 forces the oxygen out of the water to permeate through the gas porous membranes. Inside the membranes the oxygen flows away together with the strip gas. This fundamental scientific principle is described by Henry’s Law. The DGS system needs a minimum of energy and strip gas. Due to its modular design, the skid can easily be adapted to the required capacity (by parallel installation of membranes) and to the required residual oxygen content (by serial installation of membranes). The O2 content of the deaerated water is permanently monitored. Therefore, the system is equipped with a high precision optical OXYTRANS sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. For further processing, the virtually oxygen free water can optionally be cooled, disinfected with UV light or carbonated. Hollow fibre membranes are sensitive against particles in water. Therefore, Centec membrane deaeration systems contain specific pre-filters.

High precision OXYTRANS sensor for process control

Easily expandable and low consumption of strip gas

Customized modular design with a standard PLC

Skid mounted for easy installation and start-up

Hygienic execution and full CIP capability. -

TECHNICAL DATA

Capacity 2 – 2.000 hl/h

Residual Oxygen 100 ppb- <10 ppb Material according to requirements (plastics, 1.4301/AISI 304, 1.4404/AISI 316L, …) Options different automation levels; remote maintenance access; in-line O2/CO2 measurement; pre-filtration/activated carbon filtration; carbonation; disinfection; cooling

DE GAS UNIT